Blowdown Heat Recovery

Introduction

Introduction

All steam boilers must blowndown to reduce the amount of TDS in the boiler water. See Blowdown However, along with the solids, boiler chemicals and thermal energy is lost; blowdown heat recovery systems cannot recover the chemicals, but they do recover up to 90% of the heat energy that would otherwise be lost down the drain. The recovered heat is use to pre-heat boiler make-up water before it enters the deaerator, and for low pressure steam to heat water inside the deaerator, which reduces the cost to run the deaerator and improves overall boiler efficiency.

Reducing the temperature of the blowdown before it reaches the sewer drain is a typical Code requirement. Therefore, a heat recovery system also eliminates the need to dilute blowdown with cold water before it enters the sewer.

Blowdown heat recovery systems offer a fairly rapid payback, depending on blowdown volume. Several boilers can be connected to a single heat recovery unit, reducing capital costs. Typical payback is under 12 months.

A blowdown heat recovery system should be considered when:

-

~ 5% of boiler water is make-up (smaller boilers; lower percentage for larger boilers)

-

~ 500 lbs/hour steam is blown-down

-

Continuous blowdown systems of at least 1 gpm

Blowdown heat recovery in combination with Blowdown Control to both limit total blowndown volume and recover the heat is the best combination for overall efficiency.

Operation

It doesn’t matter wether blowdown is from the surface or bottom of the boiler, heat is lost along with the solids. Depending on the boiler operating pressure, steam and/or flash steam provides the most intense heat, but condensate heat recovery provides additional heating. The colder the incoming water (such as with cold make-up water and limited or no condensate return) the higher the overall efficiency.

The following diagrams show several different ways to recover the heat from blowdown. Which system makes the most economic sense will be a factor of the operating pressure of the boiler (the higher the pressure the more flash steam available), the total volume of blowdown, and the temperature and volume of the make-up/condensate return water.

The above diagram shows Flash Steam recovered for the steam distribution system and the hot blowdown condensate flowing into a heat exchanger to pre-heat incoming make-up water.

In this diagram, only flash steam is used to pre-heat make-up water in an atmospheric deaerator; the hot condensate from the blowdown is dumped to drain. It may require a cold water mixing valve to meet local codes.

In this variation, both flash steam and hot blowdown condensate are used to heat make-up water with the addition of a heat exchanger. This system works well if cold make-up water is always flowing at the same time that blowdown is occurring.

This variation adds a cold water storage tank with a circulator pump through the heat exchanger. This option means that cold make-up water and blowdown do not have to occur at the same time in order to recover heat from the blowdown condensate.

Estimating Savings

Blowdown heat recovery systems can recover about 90% of the blowdown thermal value. The value varies with volume, boiler pressure, method/frequency of blowdown and fuel cost. Continuous blowdown systems use 5 – 10% boiler capacity. Therefore, if estimating a value, 5% of average boiler capacity is reasonable. The blowdown BTU value varies with boiler steam pressure; the higher the boiler pressure the higher amount of higher value flash steam. Assume 25% flashes to steam and remainder is hot condensate for boilers under 300 psi.

The General Formulas:

Average Boiler Capacity in pounds per hour of steam x 5% = Blowdown volume

(Blowdown volume x 25% x 1,200 BTUs per Pound) + (Blowdown volume x 75% x 140 BTUs per Pound) = Total BTUs

Total BTUs x 90% Efficiency / (1,000,000 BTUs x Boiler Efficiency) = Millions of BTUs per Hour Recovered

MMBTUs x $ per MCF = Hourly Savings

EXAMPLE: 50,000 lbs per hour boiler at 200 psi steam with continuous blowdown

50,000 lbs per hour x 5% = 2,500 lbs per hour blowdown

(2,500 x 25% x 1,200 BTUs) + (2,500 x 75% x 140 BTUs) = 1,012,500 BTUs per hour in Blowdown

(1,012,500 x 90% Efficiency) / (1,000,000 x 85%) = 1.07 MMBTUs per hour

1.07 x $7.00 per MCF = $7.50 per hour = $180 per day = $5,400 per month

NOTE: In some applications the amount of flash steam produced by the blowdown recovery can exceed the amount of steam needed by the deaerator. This can lead to excessive steam venting from the deaerator and reduce the overall saving potential of the recovery system.

See also Appendix B of the CIBO Energy Efficiency Handbook 1997 Edition for sample calculations.

More Information

Manufacturers

Cleaver-Brooks

11950 West Lake Park Drive

Milwaukee, WI 53224 USA

Telephone: ![]() 414-359-0600

414-359-0600

Fax: 414-577-2715

Go to their web site at www.cleaver-brooks.com

MADDEN Manufacturing, Inc.

P.O. Box 387

Elkhart, IN. 46515

Telephone: ![]() 800-369-6233 FREE or

800-369-6233 FREE or ![]() 574-295-4292

574-295-4292

Fax: 574-295-7562

Go to their web site at www.maddenmfg.com

PENN Separator Corporation

P.O. BOX 340

Brookville, PA 15825

Telephone: ![]() 814-849-7328

814-849-7328

Fax: 814-849-4510

Go to their web site at www.pennseparator.com

Sentry Equipment Corp.

856 E. Armour Rd.

Oconomowoc, WI 53066

Telephone: ![]() 262-567-7256

262-567-7256

Fax: 262-567-4523

Go to their web site at www.sentry-equip.com

Spirax Sarco, Inc

1150 Northpoint Blvd.

Blythewood, SC 29016

Telephone: ![]() 803-714-2000

803-714-2000

Fax: 803-714-2222

Go to their web site at www.spiraxsarco.com/us

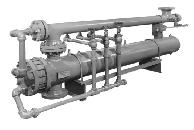

Source: Text Bob Fegan 2-2005; Blowdown separator image from National Technology Transfer, Inc. “Boilers: An Operator’s Workshop” handbook Ed.7.1; color image from www.sentry-equip.com 2-2005; heat recovery savings estimate calculations by Bob Fegan based on information available at the Madden web site; 3 version diagrams of Flash Steam heat recovery from SpiraxSarco web site at www.spiraxsarco.com/learn 3/2005;