Water Quality Monitoring

Introduction

Water quality monitoring varies from weekly litmus test strips to continuous electronic instrumentation and automated chemical treatment. The size of the boiler, the importance of water quality and the skills of the boiler operators are all factors in deciding how best to monitor boiler water quality.

Common water monitoring is for oxygen, Total Dissolved Solids (TDS), and pH. A different type of instrument is required for each.

Sample Meters and Instruments

DLR Mechanical Services

The DLS10000 series Blowdown Heat Recovery System adjust automatically to changing system demands, and recover up to 90% of the heat normally lost during boiler surface blowdown operation.

Blowdown/Heat Recovery systems will usually result in a payback in a few short months from fuel savings alone.

The DLS 10000 series Packaged Blowdown Heat Recovery System provides several features not found in other units:

-

It automatically controls the surface blowdown to maintain the desired level of total dissolved solids (TDS) in the boiler, reducing the amount of blowdown to a minimum.

-

It recovers the heat from the high temperature blowdown, and transfers it to the incoming cold make-up water, maximizing boiler efficiency.

-

The conductivity controller controls the actual boiler conductivity ( TDS ) level, keeping blowdown to the required minimum and reduces chemical costs

-

The BTU system records the actual energy saved and the amount of make-up water used. Invaluable information for the boiler operator and plant engineer

-

The Stainless Steel blowdown heat exchangers are uniquely designed to handle the blowdown and make up water. The unique spiral plate design provides U Factors as high as 1000 BTU/SqFt/Degree, and maintains high fluid velocities preventing scaling and fouling.

Significant Fuel Savings for Any Size Boiler: Transfers the blowdown heat to the make-up, thereby decreasing fuel costs.

Go to their web site at www.dlrmechanical.com

NALCO

NALCO

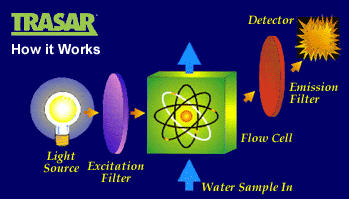

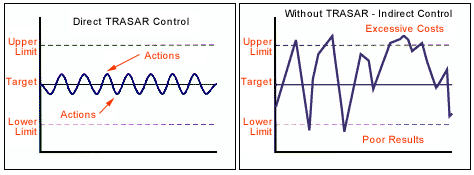

TRASAR is a versatile technology that allows Nalco to determine where its products are going during the treatment process and how effectively they are working. It solves two typical problems with today’s industrial water treatment systems: overfeeding and underfeeding. TRASAR eliminates the application of unnecessary chemicals, saving the customer money. TRASAR also prevents underfeeding, thus eliminating poor performance and extending equipment run life.

Direct, real-time control by TRASAR measures the actual chemical level in the system. Chemical injection systems linked to the TRASAR controller keep the treatment at the target levels, continuously making automatic adjustments. The results include: greater accuracy, tighter control and better reliability than indirect control.

Nalco Company

1601 W. Diehl Road

Naperville, IL 60563-1198

Telephone: 877-813-3523

Fax: 630-305-2900Go to their web site at www.nalco.com

More Information

Oxygen Control (burner and flue gas monitor)